CONTROL SYSTEMS

FADAS™ is Vital Link Europe’s Fully Automated Data Acquisition System developed using commercial off the shelf equipment (COTS). Whether for military or civilian operators, MROs, or developers, FADAS™ provides effective engine testing utilizing proven National Instruments LabView technology. As part of the Atec team, VLE also offers access to ADAQ™, ENDAS™, EDACS™, JETI, SETI, TPTI and NGEN™ control systems for our worldwide clients.

FADAS™ software is configurable for a wide range of functions and settings. Automatic engine starting, shutdown and specific engine testing, can be provided, while engine parameters are monitored. The test profiles may also be configured by the end user to allow for periodic modification to the engine running procedures. FADAS™ monitors parameters for warning and alarm conditions. Exceeding set thresholds results in many automated actions such as audio and on-screen visual cues, event logging and automated engine shutdown. Atec, Celtech and NETS also offer data systems. VLE is now underway on 2 state of the art DAS projects in Europe for jet and shaft engine applications. VLE has recently completed 3 turboshaft DAS and facility control/PLC projects and is near completion on FCMS/PLC systems for multiple thrust engine cells.

ADAQ™ is Atec’s custom engine test software and system, also built upon the industry-proven National Instruments LabVIEW and LabWindows™/CVI. ADAQ™ is a modern, full-featured, highly integrated hardware and software solution that is applicable to most commercial and military turbine engine test cell applications. It is robust, versatile, user friendly, and specifically designed to handle the demanding requirements of engine testing. ADAQ™ links seamlessly to digital engine modules (FADECs, DEECs, EECs, ECUs) as well as older analog and mechanical controls. ADAQ™ has been designed and improved since version 1.0 in 2006. Users can create, remove, calibrate & display channels, and generate custom calculations, screens and reports. Hardware flexibility with PLCs, Console layouts, UPSs, Input devices and custom user Interfaces offer popular options, so important to today’s Commercial customers. Beyond the most impressive manual throttle control and operation available, ADAQ™ 3.8 now offers the option of fully automated test.

Through collaborative efforts with Atec, Celtech and NETS (formerly w/ Astronics), we can now offer upgrades for ENDAS II™, ADAQ™, EDACS™, JETI™, SETI™, TPTI and NGEN™. Through this collaboration, our systems can test: JT8, JT9D, CF6, CFM56, V2500, F100, F101, F108, F110, F119, F135, J85, F404, F414, F124, F125, TFE 731, TPE 331, T38, T53, T55, T56, 501D, AE2100, T63, T64, PT6, T700, T701, A250, RR300. ADAQ™ is now USAF approved for control of T20 jet, T4 jet, T21 turboprop and T24/33 FEDS test cells. ADAQ™ has FAA certification/approval for a long list of commercial engines, APUs & test benches for over 50 customers at 70+ locations worldwide. Typical Intermediate and Depot level configurations are available to match popular user requirements. In addition to our data acquisition experience, Vital Link Europe, routinely handles Programmable Logic Controller (PLC) facilities systems integration, as well as power and utilities interfacing. For users in Europe, Africa and Asia, support from our London and Dubai offices are now nearby.

Key Features

- Multi-Engine Capabilities

- Analogue & Digital Displays

- Alarm Panels, Audio and Visual Cues

- Transient & Steady State Recording

- Event Logs, Data Prints to Required Formats

- Critical Systems Redundant & Power Back-Ups

- Customized Displays

- Digital I/O

- Data capture and processing of multiple signal types

- High System Accuracy

- System Scan Rates up to 1000 Hz per Channel

- Real Time Data Logging, Trend Tool Displays Engine Paramaters

- Standard Day Data Processing

- Vibration monitoring, FFT & Spectrum Analysis

Systems Components

- PC Host Computer running Windows 10/Windows 7 Pro and FADAS System, Control and Calibration software. DVD R/W, Laser Printer, Multiple widescreen LCD Displays, dual hard drive for increased data storage capacity

- System designed using National Instrument Hardware PXI

- Designed for harsh environments

- PLC – Engine/Facility Controls

- Operator Engine/Facility Control Interface

- UPS providing backup power for the DAQ system during power failures

- Now collaborating on ADAQ, EDACS, ENDAS, JETI, SETI, TPTI and NGEN systems

THROTTLES

V ital Link Europe has produced throttle systems specifically designed for both Jet Engine and Turboshaft engines for many years. The Throttle Systems we now have available offer a wide, proven array of features to meet you testing needs and preferences. Our original throttle utilizes a position demand input from a manual lever, potentiometer, or from software control mechanisms. An Emergency Stop push-button option can be integrated. The throttle input demand position operates either a stepper motor, or an electrical signal, to provide the required signal or motion on the engine. When operating a rotational device, our throttle utilizes high accuracy encoders mounted on the stepper motors to ensure positional accuracies from initial movement to the final stop position. FADAS™ continually monitors engine safety parameters and commands the throttle to return to idle or cut-off. Operators may regain control of the throttle by moving the physical input lever. Our throttle and DAS offerings have now been bolstered by our merger with Atec, Celtech and NETS (formerly w/ Astronics) whom offer fine throttle and DAS systems. When reviewing your engine control needs, we will make sure you get the throttle that best fits your needs.

Features

- Replaces legacy throttles

- Interfaces with all modern electronic DAS and DEEC controls

- Manual, Semi-Automatic and Automatic programmed throttle movement

- Pushbutton controls integrated into throttle handle assembly

- Throttle can be “rigged” via local pushbutton menu system or from computer software

- Programmable electronic position stops and speeds

- Velocity stick for manual positioning and setup

- Stand-alone operation or remote control via Ethernet, TCP/IP

- Velocities or speeds can be set via Ethernet prior to executing a position change

- Remote commands can select almost any speed

- Mechanical mounts and engine shaft adapters interface to different engine types

- Integrated “Idle-Hold,” “Cut-Off Enable” and “Drive Disable” switch functions

- Now collaborating on Atec, Celtech & NETS throttles and DAS systems

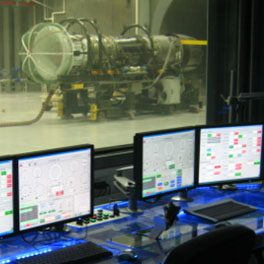

CONTROL ROOMS

V ital Link Europe offers control cabs that can host FADAS™, ADAQ™, ENDAS, EDACS, JETI, SETI, TPTI, NGEN™, FEDS, PC4 and other control and data acquisition systems. All are extremely rugged and designed to minimize noise transmissions into the cab. Enhanced sizing provides more space for operators and equipment, and maximizes comfort for the operators.

Our Control Cabins are easily moved with a fork lift and features shock mounting. Options for running gear provide standard towing capability for on-base/on-airport mobility. Atec and Celtech design and manufacture control cabins and control room modules as well.

CAMERAS & INTERCOMS

V ital Link Europe has installed cameras and video systems at multiple locations to provide monitoring during engine testing. The systems act like a window to provide remote viewing. The camera and video monitoring systems are durable, remotely controlled, and distortion free. Our systems can display multiple image feeds, or a single feed for more detailed inspection.

VLE also installs dual-channel wireless intercom systems for communication between the control room and the test cell in many of our projects. Our intercoms include models to enable low noise talk between test cell, aircraft and control room. In addition to internal designs, we also offer access to the full catalog of popular Atec products, Vital Link, NETS and Celtech Products.